REFINING

Refining to 999.9 Purity Gold Coast Refinery

Achieving a 999.9 purity level for gold is a testament to a refinery’s technical expertise, advanced equipment, and unwavering commitment to quality. Gold Coast Refinery stands as a prime example of such excellence.

The Journey to 999.9 Purity

To attain this extraordinary level of purity, a multi-faceted approach is employed:

- Initial Purification: Impure gold, often in the form of doré bars, undergoes initial purification processes to remove base metals. This typically involves methods like electrolytic refining or acid parting.

- Aqua Regia Dissolution: The partially purified gold is dissolved in aqua regia, a potent mixture of nitric and hydrochloric acids. This process converts gold into a soluble form for further purification.

- Precipitation and Purification: Gold is precipitated from the aqua regia solution using reducing agents. The resulting precipitate is then subjected to rigorous purification steps to eliminate traces of impurities.

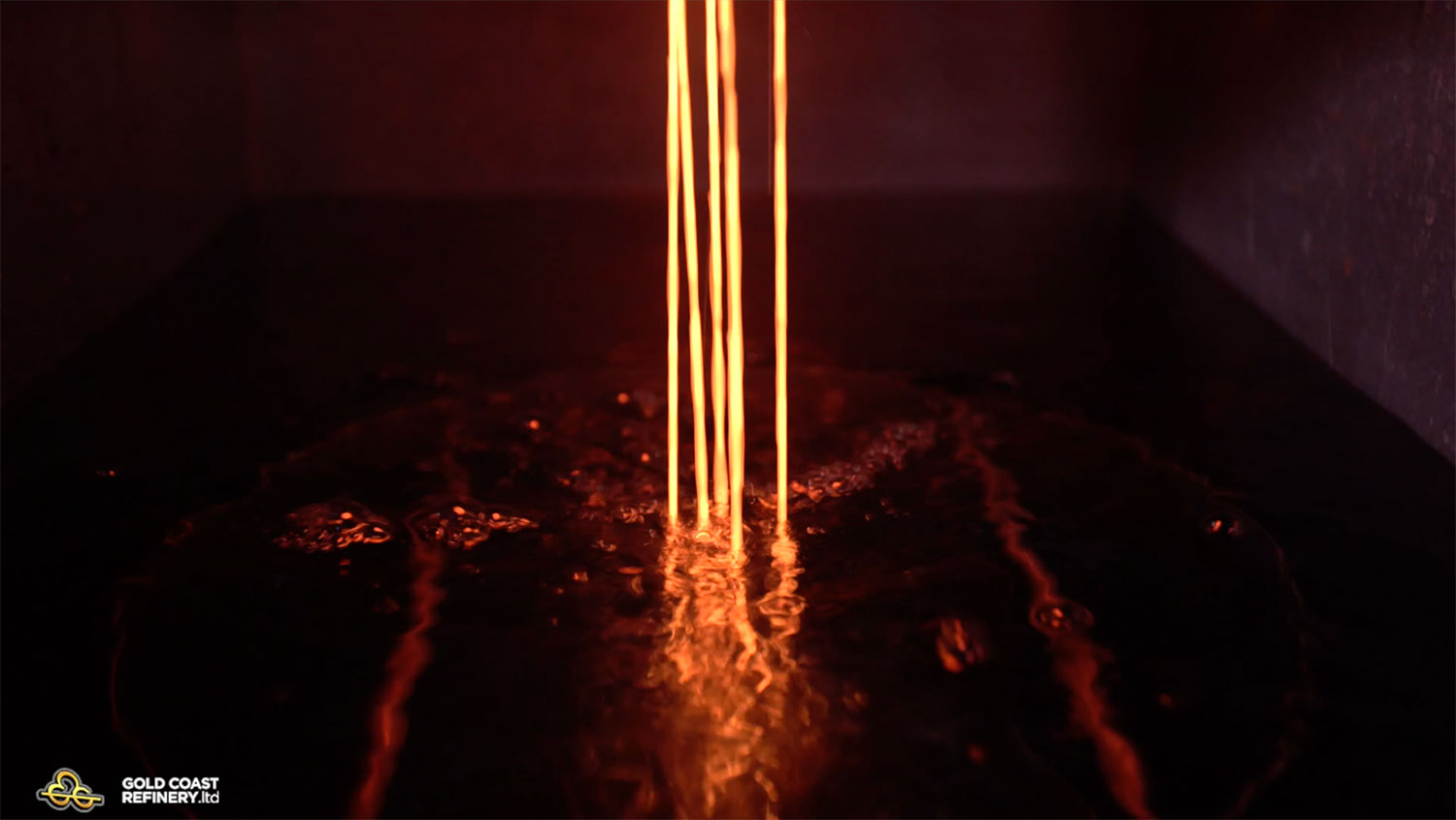

- Electrolytic Refining: To achieve the final stages of purification, electrolytic refining is employed. This process involves passing an electric current through a gold solution, causing pure gold to deposit on a cathode.

- Melting and Casting: The refined gold is melted and cast into standardized gold bars. The casting process is conducted under controlled conditions to prevent contamination.

Quality Control and Assurance

Ensuring 999.9 purity requires an ironclad quality control system:

- Regular Assaying: Frequent and precise assays are conducted throughout the refining process to monitor purity levels.

- Spectrographic Analysis: This technique identifies and quantifies trace impurities, providing a detailed elemental profile of the gold.

- Inductively Coupled Plasma Mass Spectrometry (ICP-MS): For the ultimate in precision and sensitivity, ICP-MS is employed to detect even the minutest impurities.

- Independent Audits: External audits by accredited laboratories verify the refinery’s claims of purity and adherence to industry standards.

Environmental Considerations

While pursuing purity, the Gold Coast Refinery is committed to environmental responsibility.

- Waste Management: The refinery implements strict protocols for the management of hazardous chemicals, such as those used in aqua regia.

- Emission Control: Advanced filtration systems and emission control devices minimize the release of pollutants into the atmosphere.

- Energy Efficiency: The refinery adopts energy-efficient practices to reduce its carbon footprint.

By combining advanced refining techniques, stringent quality control, and a strong commitment to environmental protection, the Gold Coast Refinery has established itself as a leader in producing gold of unparalleled purity.